5 Tipps - Wartung und Pflege von Spritzgussformen

Proper maintenance of injection molds is essential to ensure consistent performance, longevity and quality of the produced pieces. In this article, we will explore some practical tips to help look after your molds, extending useful life and optimizing efficiency.

1. Comply with maintenance plans– It is a differentiator point and extremely important to guarantee the efficiency and quality of the production process. This practice helps to minimize failures and wear, prolonging the useful life of the molds and avoiding unwanted stops in production.

2. Regular Cleaning– Regular cleaning of molds is essential to prevent residue build-up and ensure a smoother injection process. Use suitable tools, such as soft brushes and compressed air, to clean the internal surfaces of the molds. Avoid using abrasive chemicals that can damage mold surfaces.

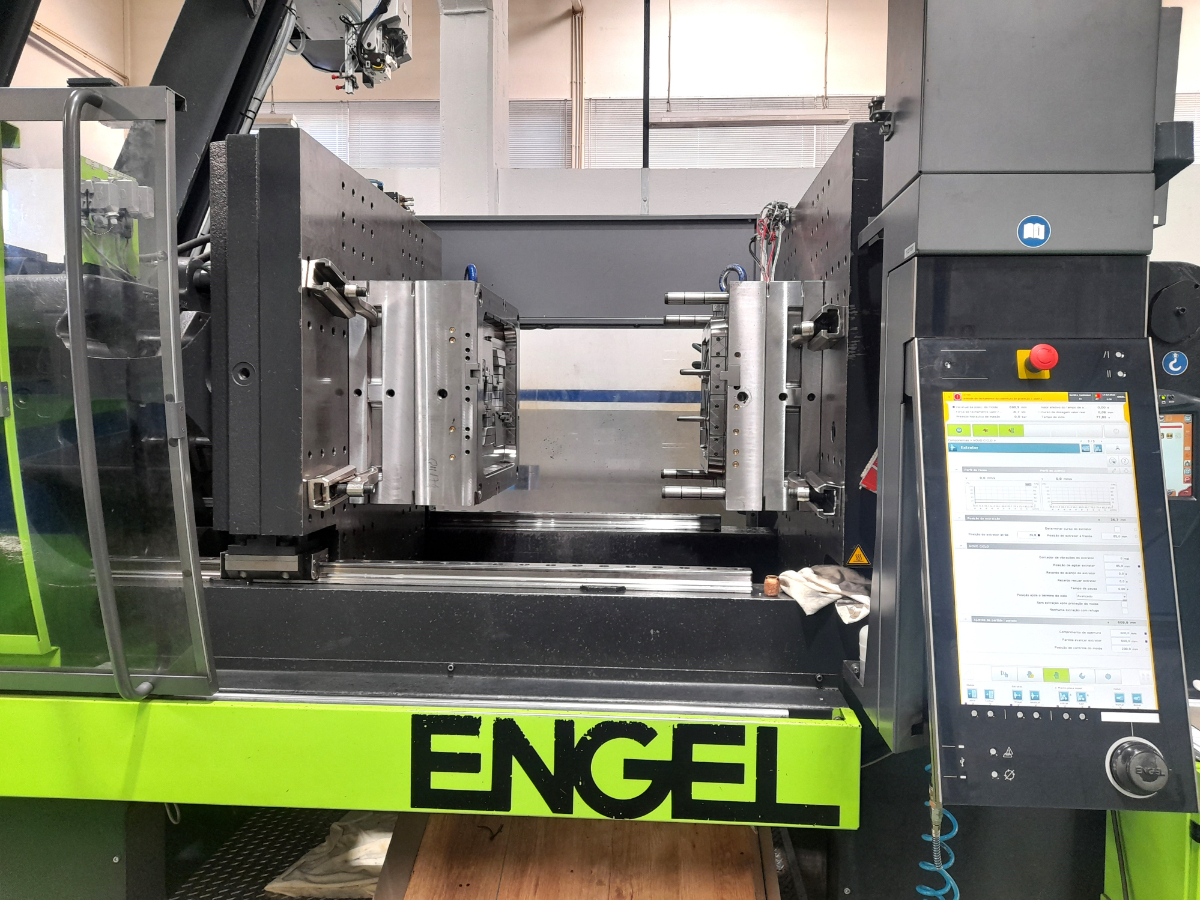

Mold on an Engel injection molding machine

3. Proper lubrication– Mold lubrication plays a crucial role in preventing wear and corrosion. Use lubricants recommended by the manufacturer and apply them to the appropriate areas, such as guides, extractors, rods, slide plates and movements. Be sure to follow application instructions and avoid over-lubrication, as lubricant build-up in certain areas can compromise the mold's work.

4. Regular Inspection– Perform periodic inspections of the molds to identify any wear, damage or problems. Carefully check surfaces, cavities and cooling channels for signs of excessive wear, corrosion or debris build-up. If necessary, make immediate repairs or replacements to prevent additional damage to the molds to ensure there are no downtimes and part quality is not compromised.

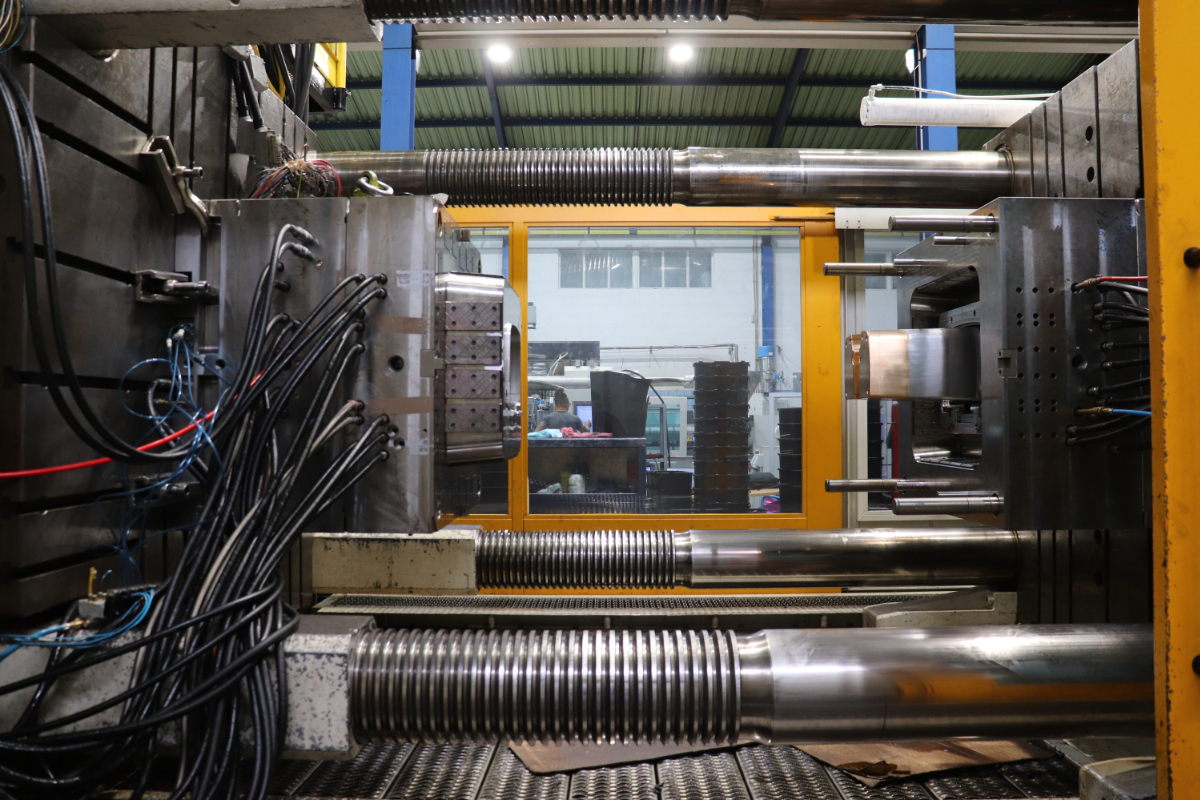

Mold in a Krauss-Maffei 1600 Ton injection machine

5. Professional repairs– When necessary, turn to companies that specialize in mold repair and maintenance, as they have the appropriate knowledge and tools to handle complex repairs and ensure molds are restored accurately. Quickmold performs all types of injection mold repairs. If you have recurring problems with your molds, know that we have the capacity to modify the engineering, types of materials and parts in the molds, in order to correct these flaws and increase the longevity of the molds.

Proper maintenance and care for plastic injection molds are essential to guarantee the quality and efficiency of the production process. By following the tips mentioned in this article, you will be contributing to the longevity of your molds, reducing replacement costs and maximizing your company's productivity. Always remember to consult the mold manufacturer’s guidelines.

Did you have any questions? Don't hesitate to contact us.