Wie kann man Kosten in der Kunststoffspritzgussindustrie senken?

“For over 20 years manufacturing molds for the plastics Industry, I can say that good mold construction is directly linked to cost reduction in the plastic injection industry, which is highly competitive. This can be a determining factor in the success of your company." Pedro Correia - CEO Quickmold

Managers are constantly looking for more and more effective ways to reduce costs, and that is a big concern. The costs of raw materials, energy, and workers are very volatile and can compromise the profitability of your business.

Today, I will address 3 important points about plastic injection molds:

- Maintenance;

- Refrigeration;

- Choice of Materials.

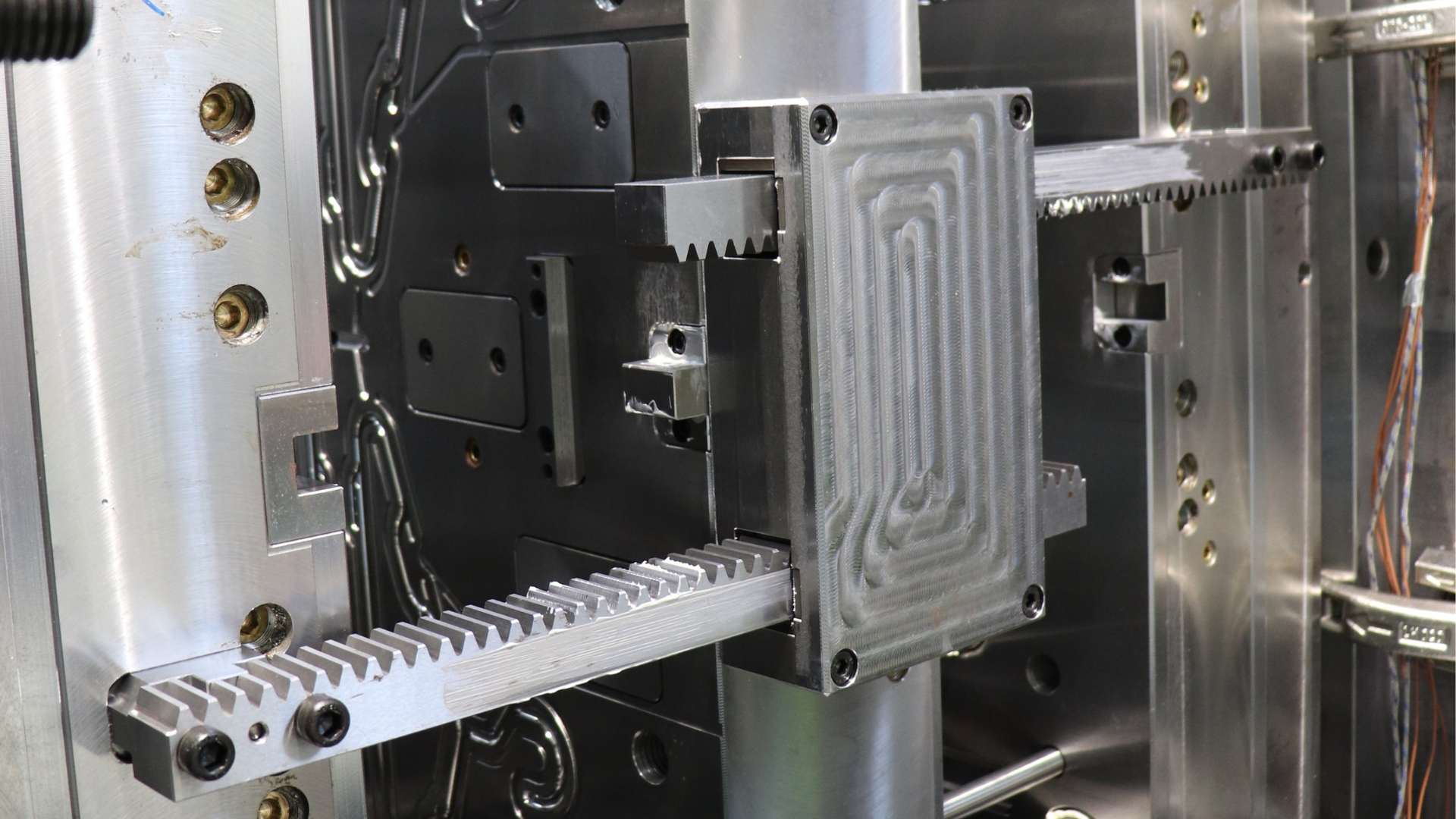

Sandwich mold

Maintenance

A good way to reduce costs is through good mold maintenance. When they are of low quality or poorly maintained can lead to longer cycle times, greater waste of raw materials, and production delays. It is important to invest in high-quality molds with good construction to make maintenance easier and minimize downtime.

Refrigeration

Another important factor is the proper construction of the molds, especially when it comes to good refrigeration. Mold cooling, with independent circuits, helps with temperature control and can significantly reduce cycle time, allowing more parts to be produced in the same period.

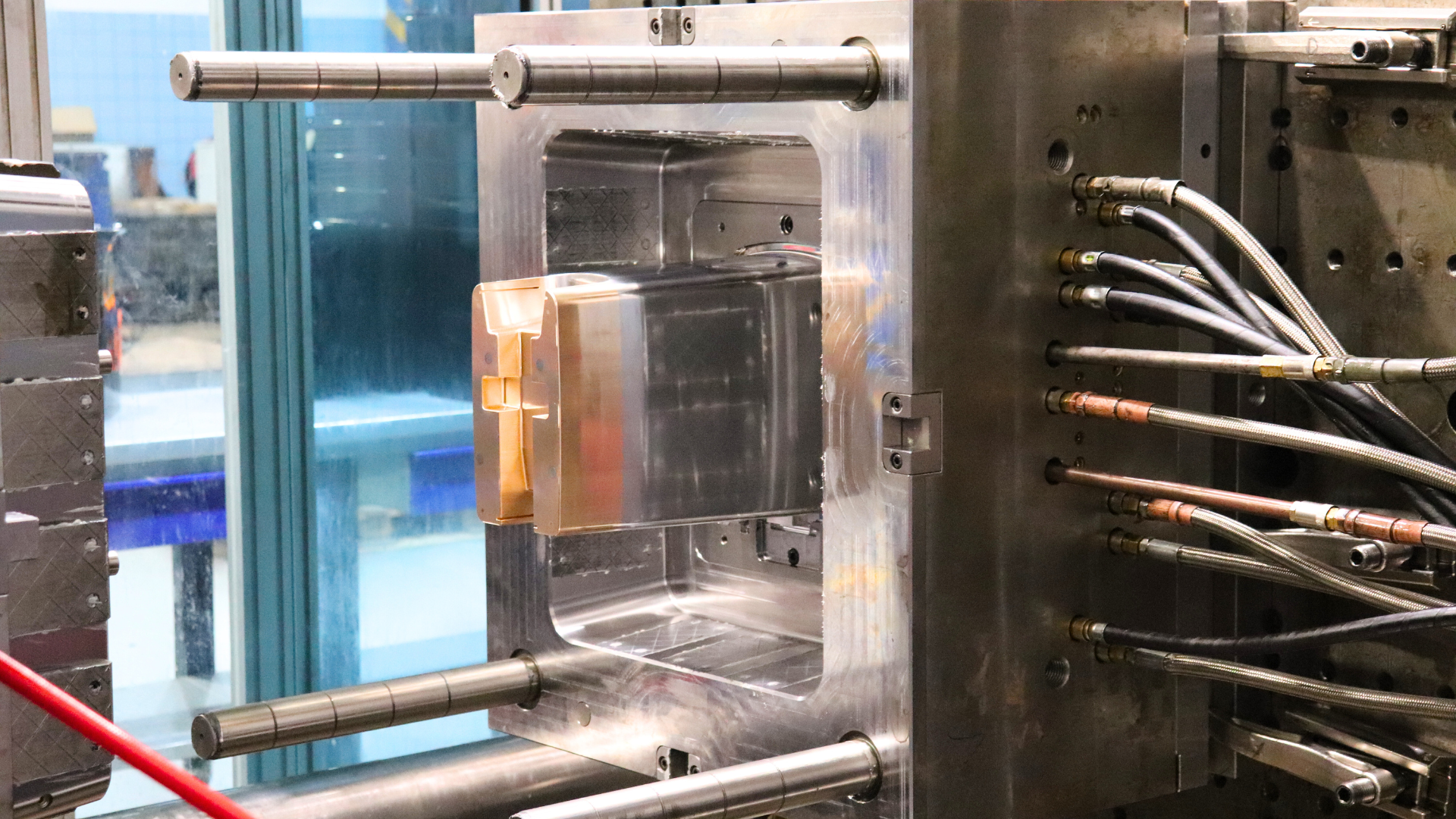

Mold cooling with carburetors

Materials

Choosing suitable materials for mold construction is a very important factor. Depending on the application, the choice of special alloys such as Beryllium Copper (CuBe) can be quite advantageous in terms of refrigeration and mold durability. There is also the issue of heat treatments that we perform on parts and most critical elements of the mold, this is the only way to guarantee the excellent functioning and durability of the mold.

Mold with beryllium copper insert

It is important to highlight that cost reduction in molds cannot compromise the quality of the final product.

At Quickmold, before starting any project, we are aware of the following points:

- Proper selection of materials;

- Study of efficient mold cooling, which reduces cycle times;

- In the 3D mold design phase, we pay attention to several points that help in mold maintenance, reducing downtime.

Contact us and find out about these and other mold production practices that reduce cycle times, and raw material waste and increase your company's profitability.

Quickmold - inside facilities