WHO WE ARE

VisION

Quikmold's vision is anchored in the mission of generating value. We add value to the market in a differentiating way as a strategic and reliable partner, which values solid and lasting partnerships with its customers. Focused on delivering to the customer a sustainable and complete value offer - from the moment the plastic part is just an idea, to the delivery and support of the mold - Quickmold is based on trust, transparency and accuracy, guided by values such as simplicity, knowledge sharing and especially by keeping our word.

HistORY

METHODOLOGIES

1

Commercial agreement and mold contract

2

Analysis of requirements and preliminary 2D drawing

3

3D printing and design analysis

4

Filling/Moldflow studies

5

6

Mold manufacturing

7

First trials and dimensional control of the samples

8

Customer feedback and necessary adjustments

9

Shipment of the mold

10

After sales support and service

EQUIPMENT

Description | Brand | Dimensions |

RPM |

| Machining Centre CNC | Perfect Jet | 2500 x 1600 x 1000 | 10.000 |

Machining Centre CNC | Huron KX30 | 1800 x 1000 x 600 | 18.000 |

| Machining Centre CNC | Huron KX20 | 1200 x 1000 x 600 | 18.000 |

| Machining Centre CNC | Surefirst | 1500 x 1000 x 700 | 15.000 |

| Machining Centre CNC | Goratu | 1100 x 800 x 550 | 18.000 |

Electric Head | SFIDA | - | 60.000 |

Penetration Erosion | Ona Matic | 300 x 400 | 650 x 400 x 400 |

| Penetration Erosion | Charmilles | 1300 x 800 x 600 | - |

Grinding Machine | Monoprecis | 350 x 200 x 300 | - |

Grinding Machine | LGB | 2100 x 1300 x 500 | - |

| Lathe | Graziano | 600 x 1500 | - |

Drilling Machine | MAS V050 | 2500 x 1600 x 1500 | 2.500 |

Thermal Cones Induction Machine | Dine | - | - |

| Horizontal Saw | - | 300 x 400 | - |

| Vertex Cutting Machine | Vertex | 500 | - |

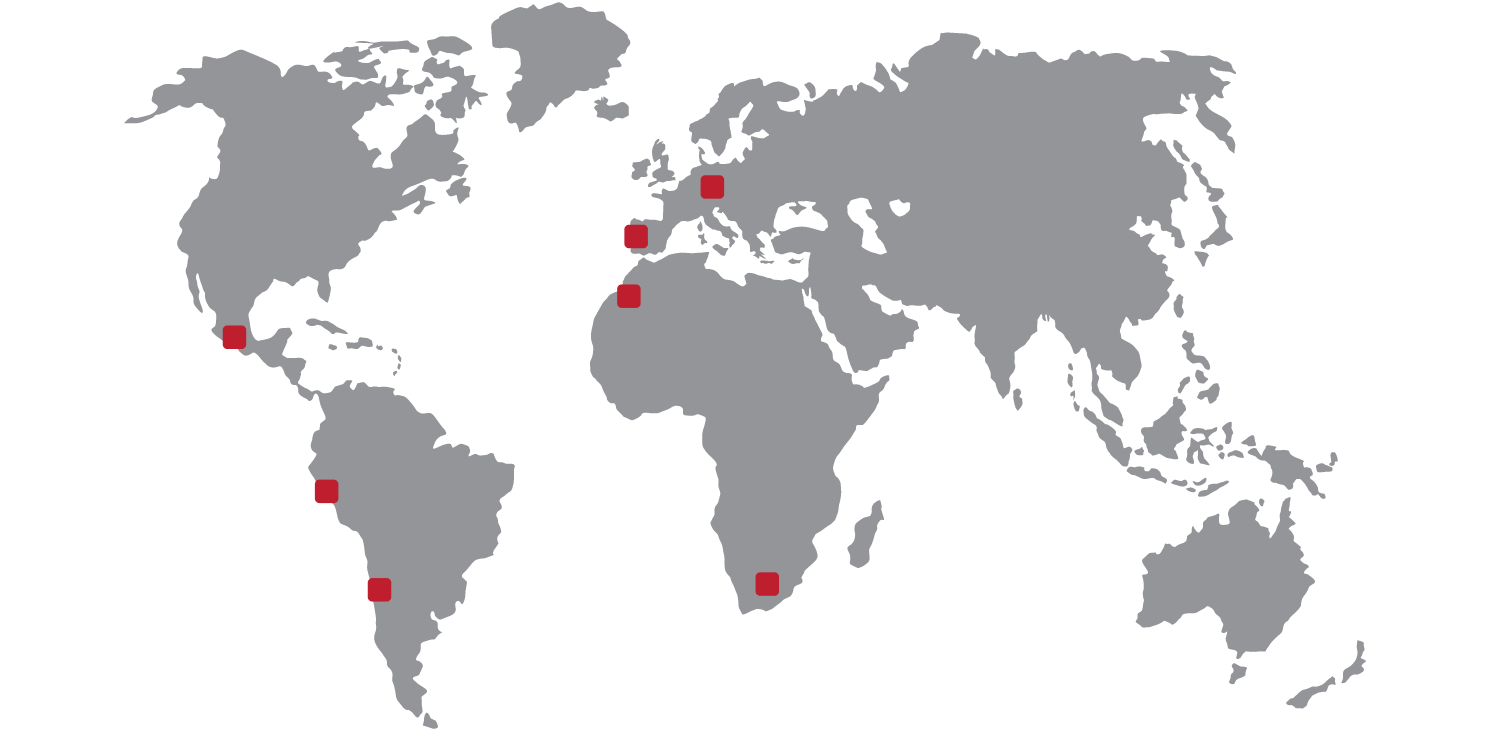

QUICKMOLD IS PRESENT ON 4 CONTINENTS